Faser’s core line of business is manufacturing, processing, and selling fresh, natural fruit pulp to domestic markets and abroad. Of great importance to us is strengthening bonds with our clients, by developing a sound infrastructure that helps us offer our clients the finest quality mango pulp and other fruit pulps in our selection. Following points will give you an idea about the necessary infrastructure that we use in our day to day operations:

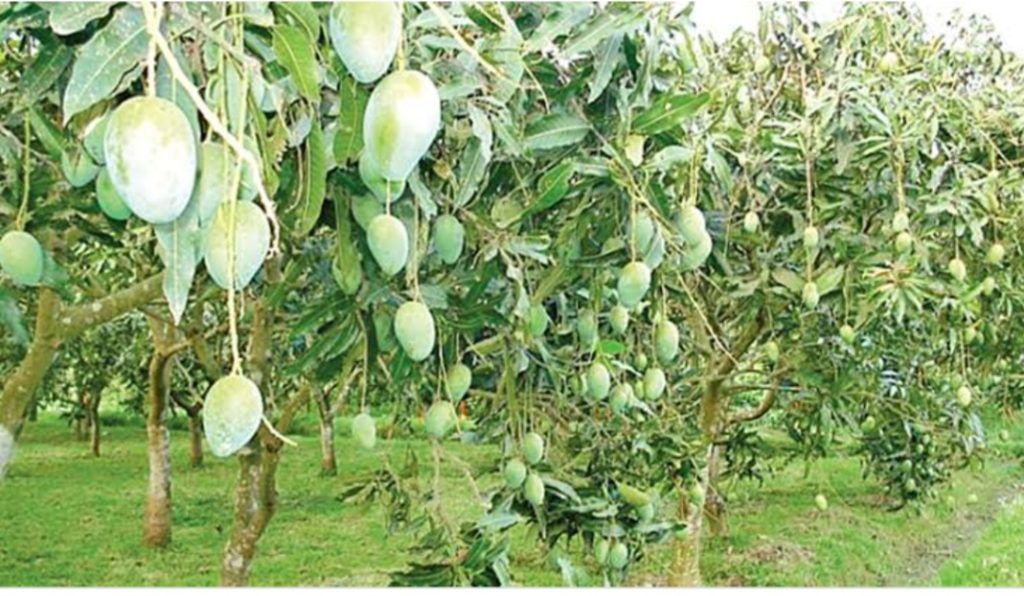

- First of all, we bring the top-notch fresh raw material, from our own orchards and from the local markets and trusted partners.

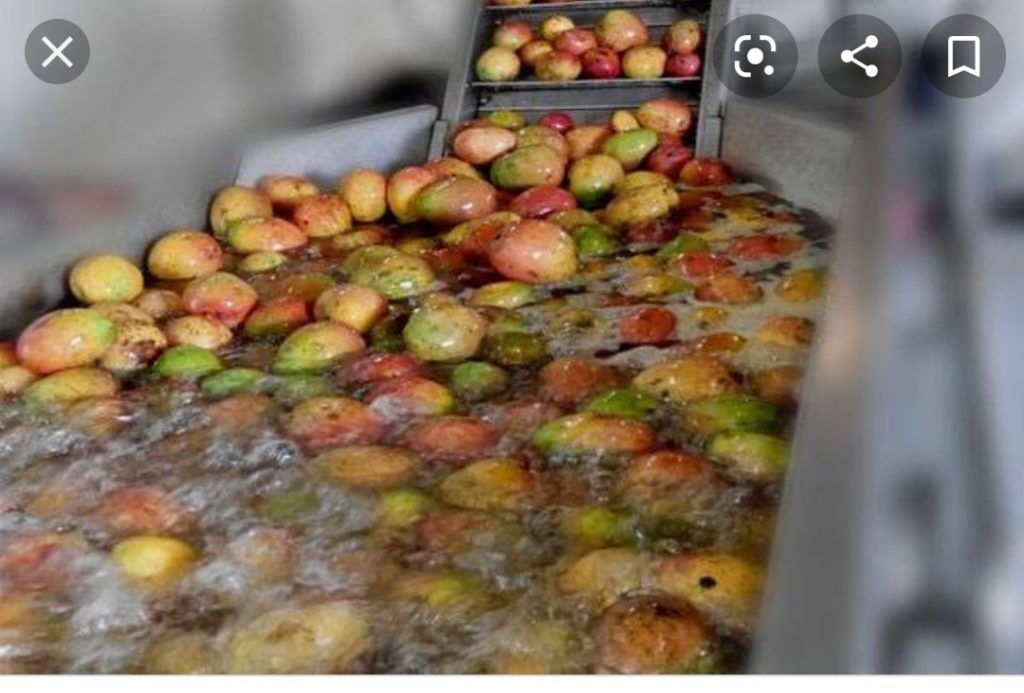

- Initial sorting is done manually on a conveyor. Any rotten and spoiled fruits are removed from there.

- After conveyor screening, the next step is water showering to achieve its washing.

- When passed through showers, the fruits drop into a tub that contains circulating water where it is dipped and cleaned again.

- Fruits are then lifted up to 20 feet higher through an elevator. Where there is our pulper who initially crushes the raw material. The seed is extracted and the remaining portion is sent to finishers.

- The finishers remove the peels and send forward the pure pulp to a storage tank.

- After storage tanks, we have placed a homogenizer that converts it into micro particles.

- Then we have a pasteurizer where pulp is heated up to 90C for the killing of any germs and bacteria.

- After pasteurization, it goes to another storage tank where it is cooled down to 40-50C using agitators.

- Once cooling and agitation is done in the storage tank, there are two scenarios for preparing pulp:

- In the first scenario, we mix chemicals in it and take it into drums where polythene bags are added to preserve it. A conveyor then moves the drums outside the building where our trained workers place lids on and put them in the storage.

- In the second scenario, no such chemicals are added. We have an aseptic filler which sterilizes the aluminum coated package material, fills the pulp into the package, and then hermetically seals the package. After that it is placed in a temporary storage for 10 hours approx. and then moved into a cold storage.

- It is to be noted that we only use stainless steel made equipment. Iron is completely avoided due to rusting and corrosion.

- The washing of the whole equipment when starting & before closing the plant is done on a daily basis and takes around 4 hours to complete the cycle.

- Our whole process is automatic with almost negligible manhandling like placing the fruits on conveyor belts. Otherwise, washing, pasteurizing, pulping, etc. are completely automated.